Bearings

For more than 200 years, roller bearings have been one of the most important machine elements. One of the most important tasks of roller bearings, similar to plain bearings, is to transmit loads between parts which are moving relative to one another and to avoid unwanted contact between these machine parts. With roller bearings, there are differently shaped rolling elements (balls, rollers or needles, cylindrical rollers or tapered rollers) between the bearing rings. Undesired sliding friction is transformed into rolling friction by rolling the rolling elements between the bearing races. The geometrical shape of the rolling element determines the size and direction of the loads to be transmitted. A distinction is made between point-contact (ball bearings) and line-contact (rolling-element bearings) roller bearings. The larger contact areas (line contact) accordingly permit larger loads to be transmitted. Where the contact area is smaller (point contact), the friction surface of the roller bearing is also smaller. This allows improved energy efficiency to be achieved.

On account of the contact area and mass, the rolling element geometry determines both the static (load ratings) and dynamic (limit speed, friction, dynamic load rating) characteristics of the roller bearing. Depending on the bearing load, the rolling element may be compressed in the respective raceway. The criterion for this is the material rigidity.

Oil or grease lubrication reduces roller bearing friction even further. Oil can serve the additional purpose of dissipating the heat caused by bearing friction.

Roller bearings are standardised internationally and can be interchanged worldwide. They stand out on account of the high-purity steel used, their modern design and high precision (tolerances). Optimised design, contemporary production accuracy, modern materials (vacuum-degassed roller bearing steels, low-corrosion stainless steels, ceramics and new polymers) including software permit additional areas of application and/or improvement compared with previous applications. The optimum selection of roller bearings in terms of price, performance and availability has been one of Wälzlagertechnik's strengths for more than 20 years.

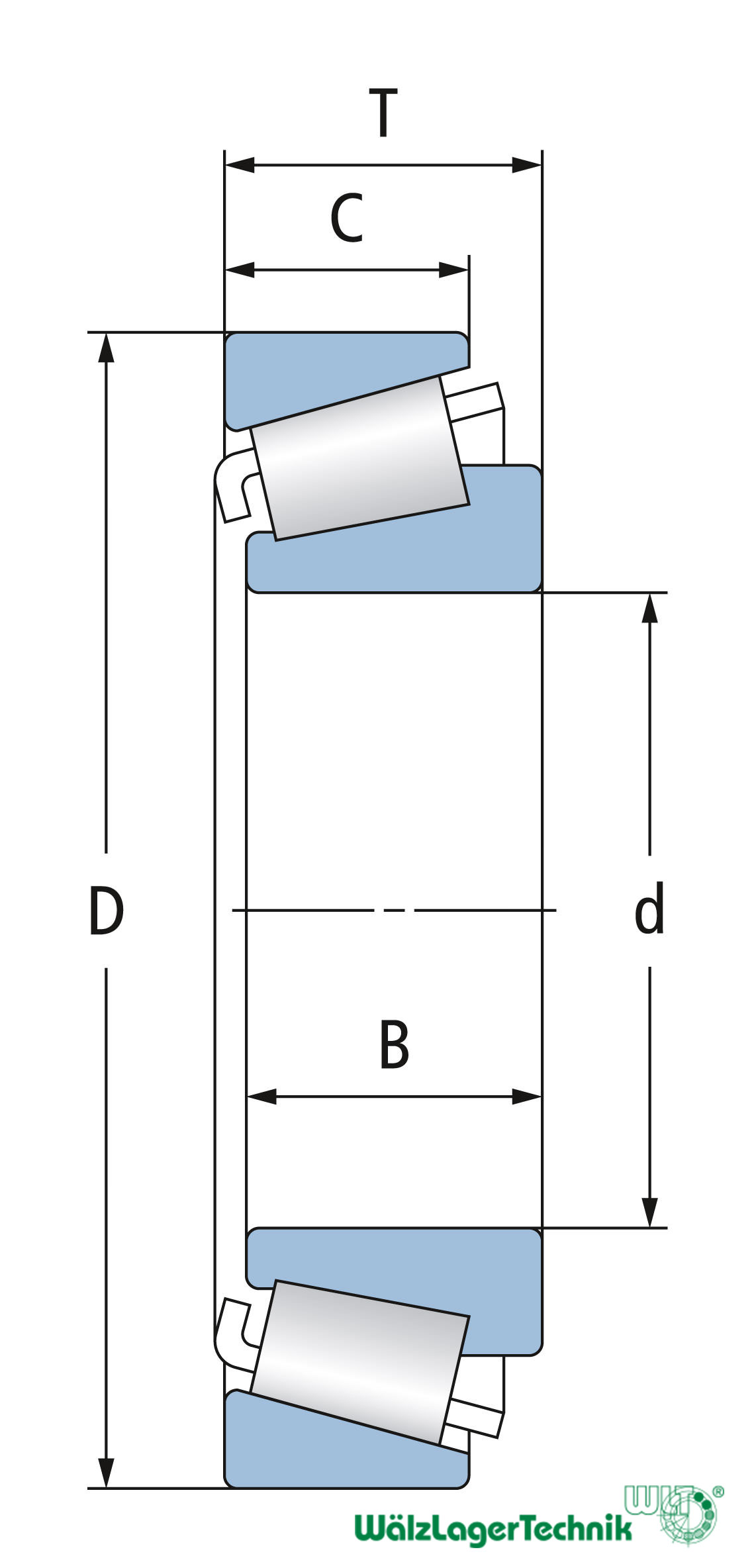

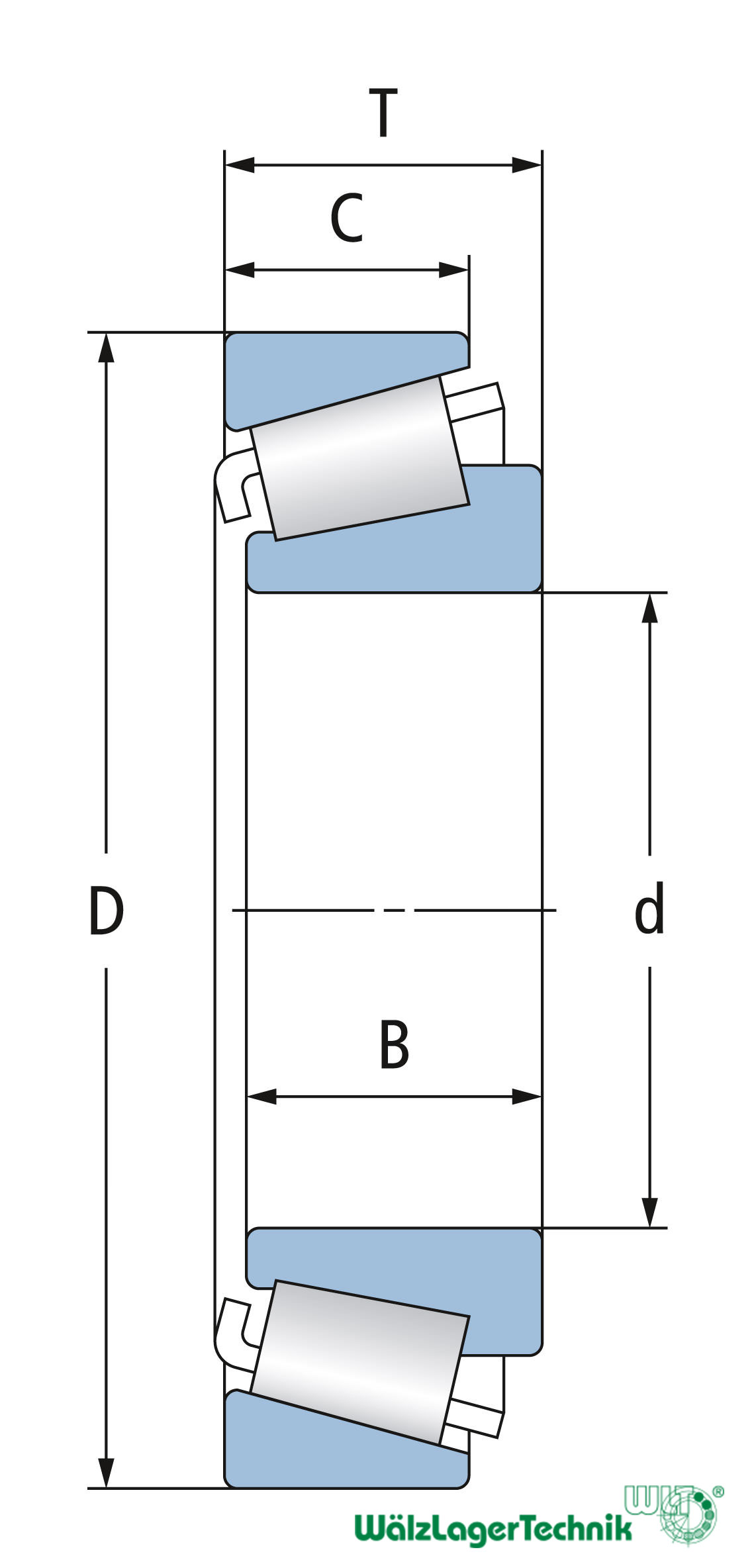

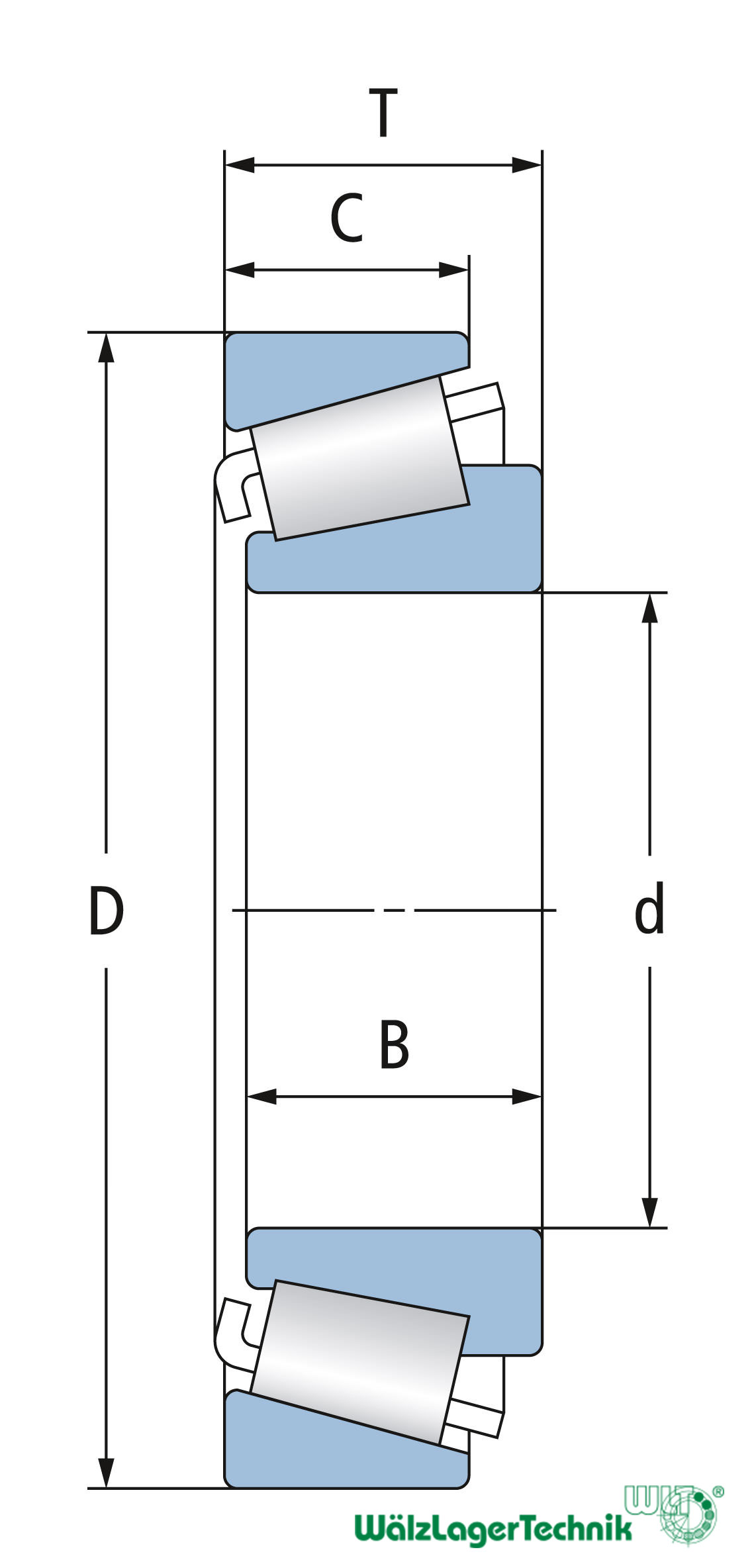

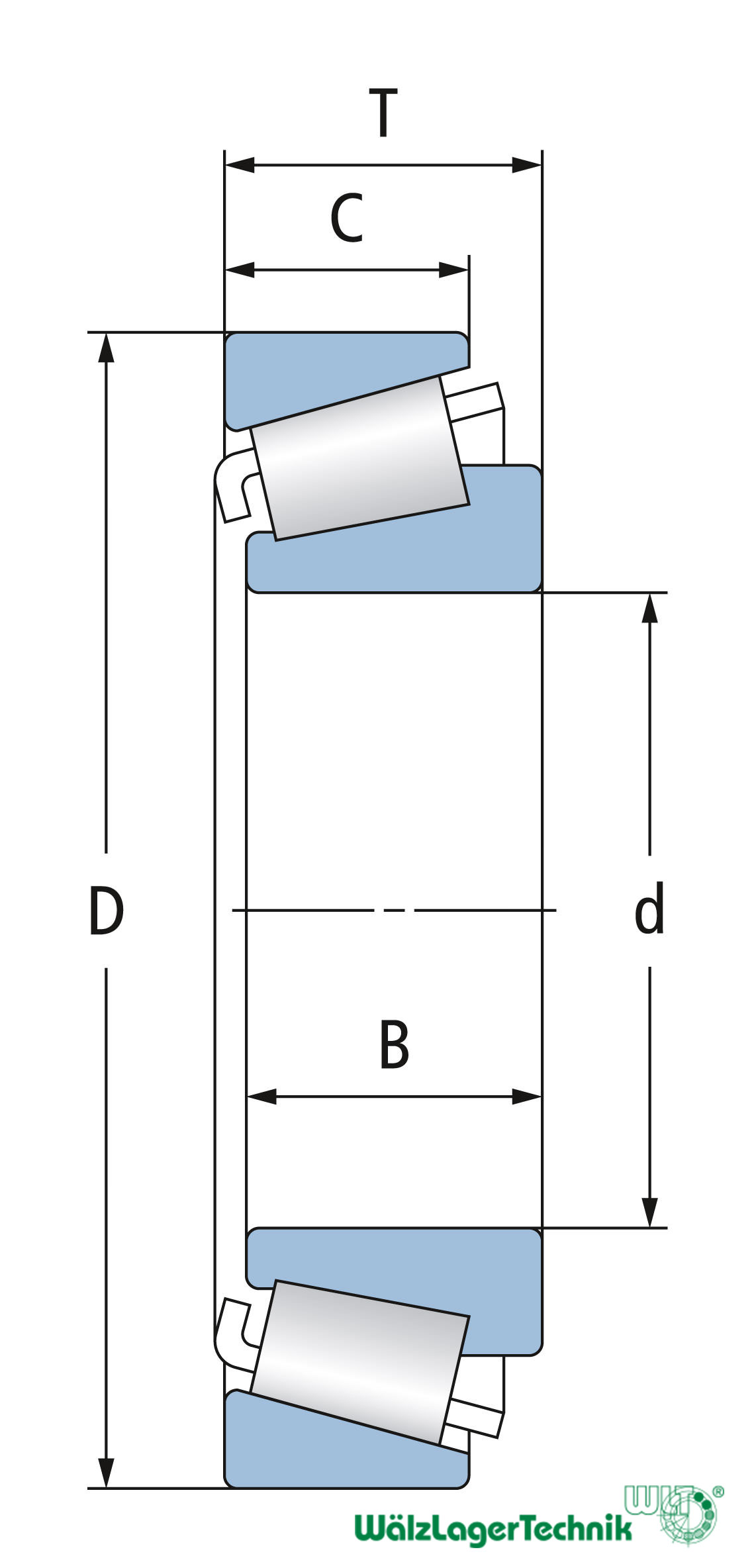

- d (mm)100

- D (mm)180

- B (mm)34

- C (mm)29

- T (mm)37

- Gewicht in kg3,83

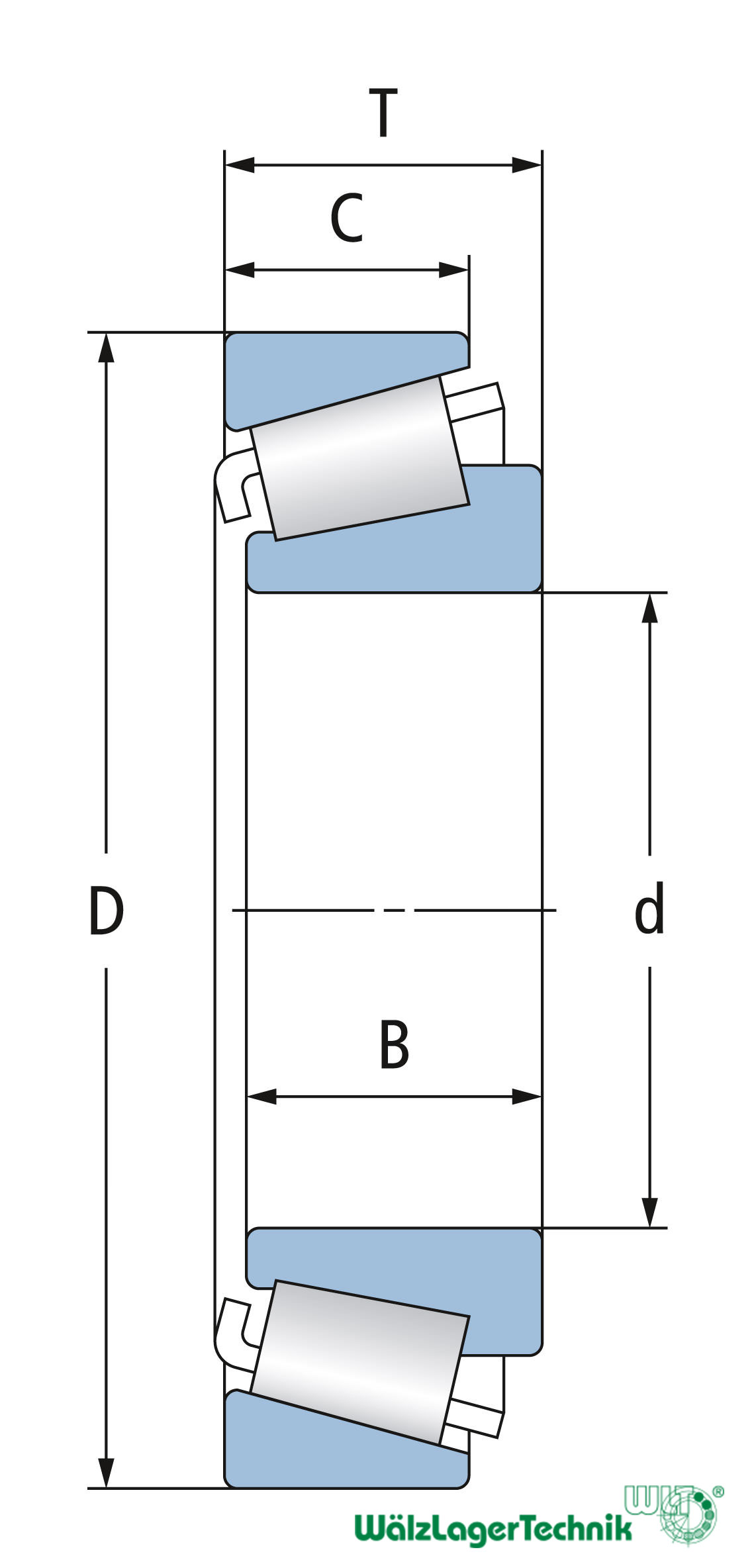

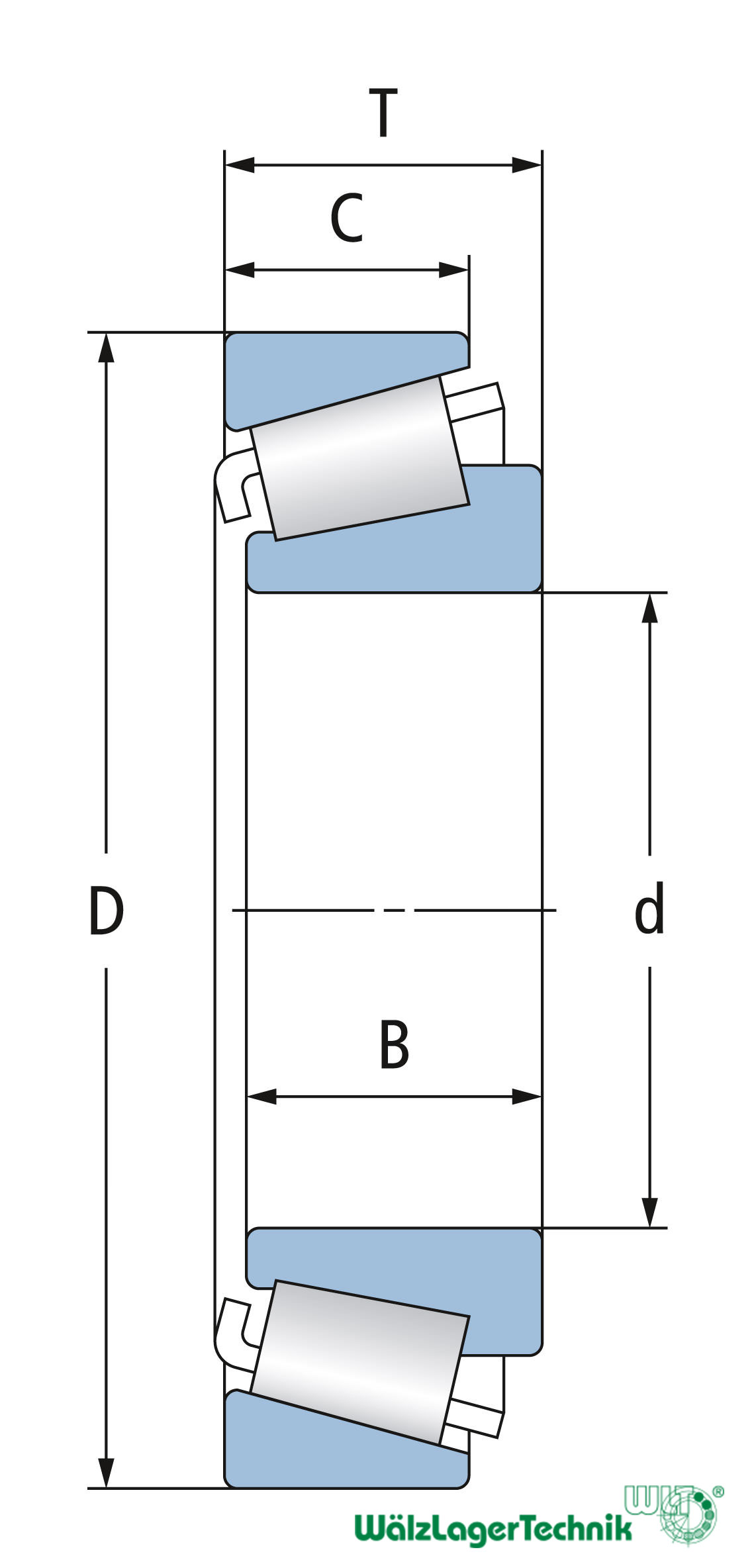

- d (mm)105

- D (mm)190

- B (mm)36

- C (mm)30

- T (mm)39

- Gewicht in kg4,49

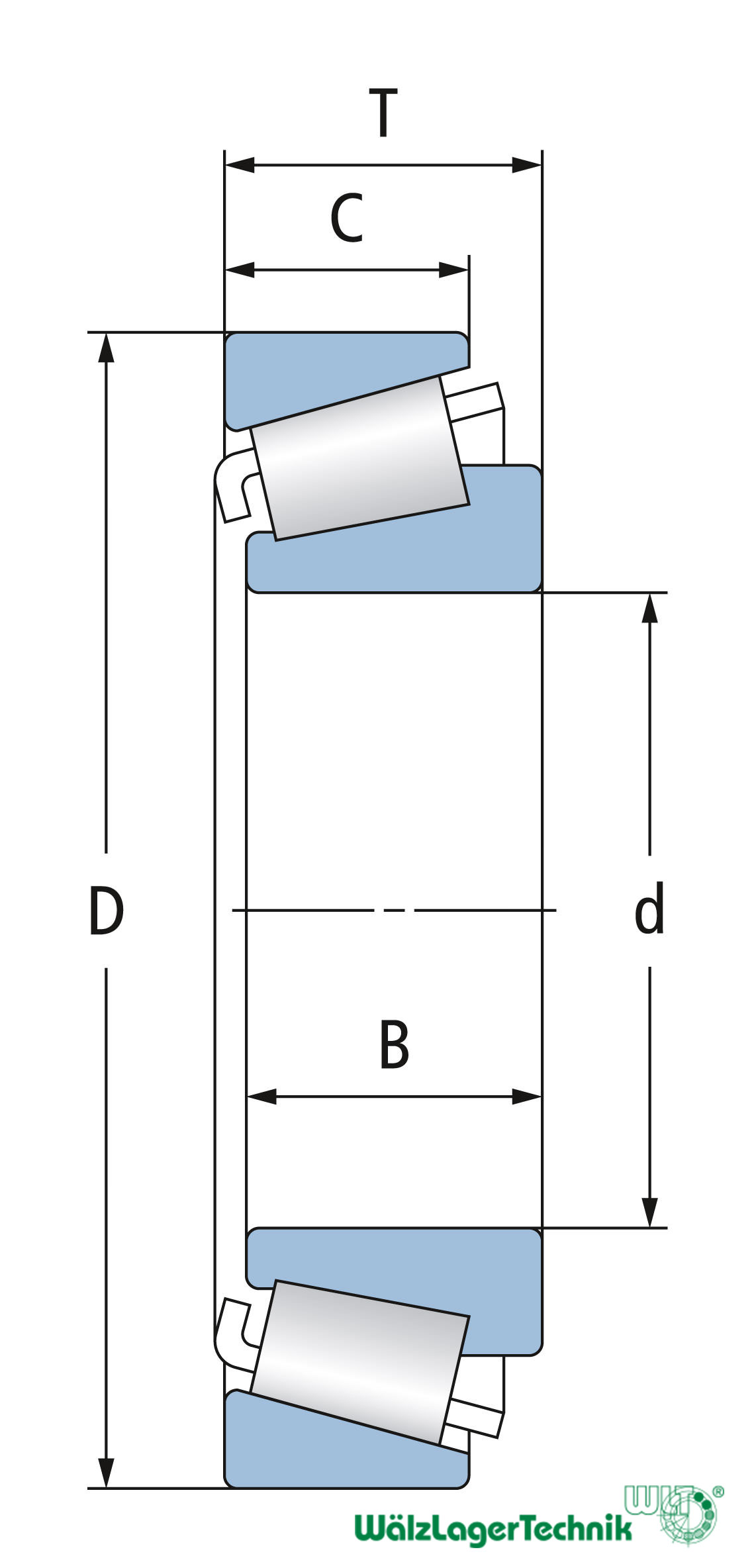

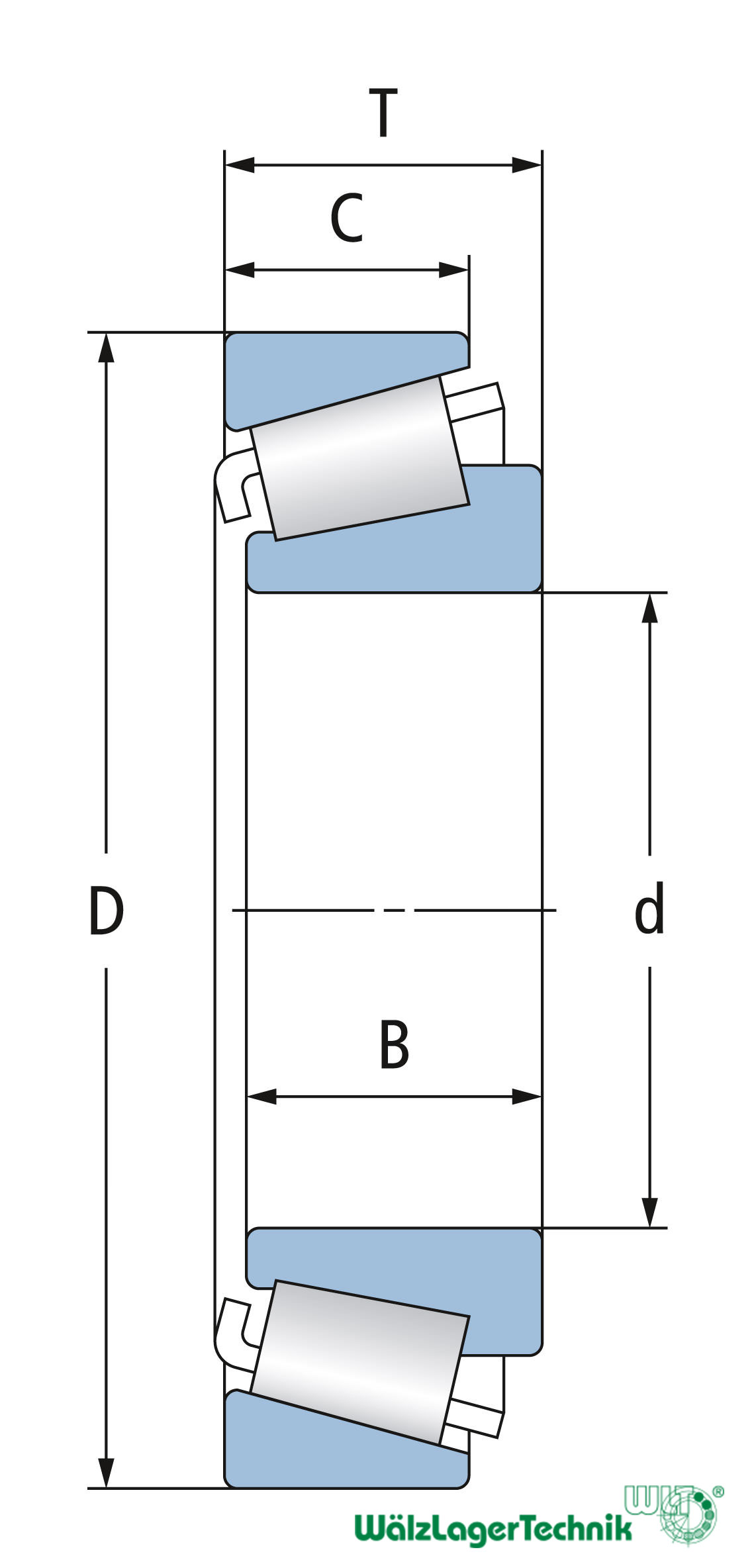

- d (mm)110

- D (mm)200

- B (mm)38

- C (mm)32

- T (mm)41

- Gewicht in kg5,33

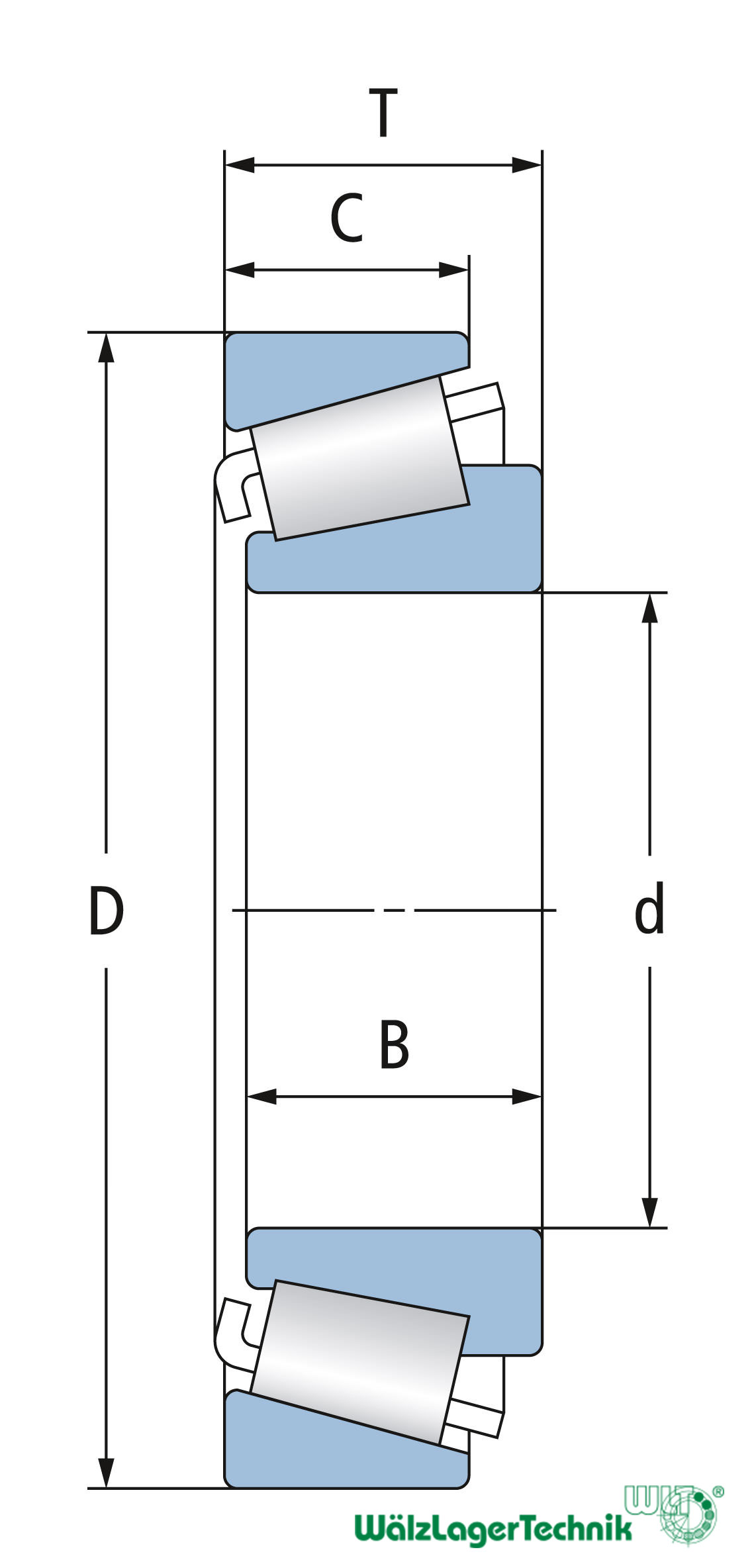

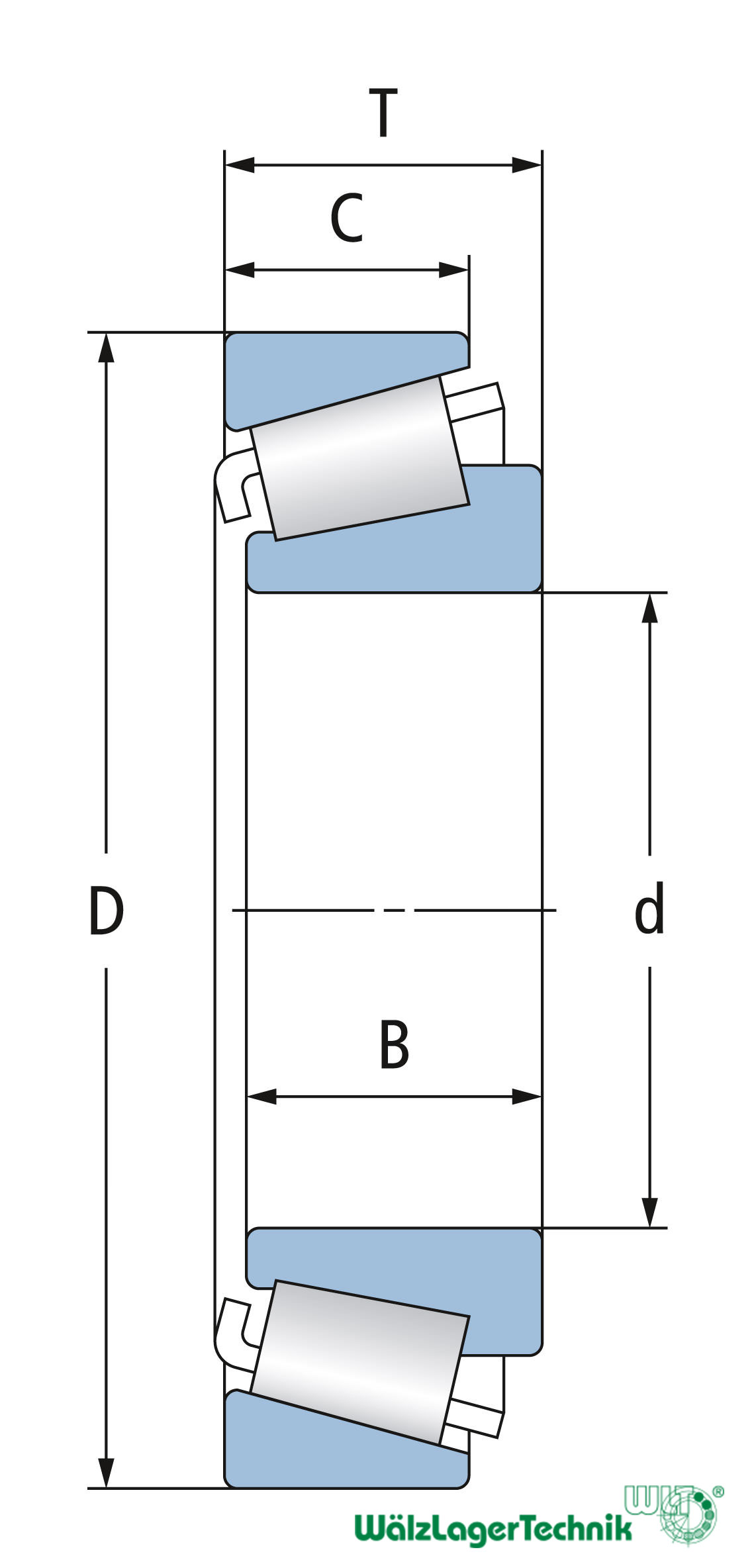

- d (mm)120

- D (mm)215

- B (mm)40

- C (mm)34

- T (mm)43,5

- Gewicht in kg6,36

- d (mm)130

- D (mm)230

- B (mm)40

- C (mm)34

- T (mm)43,75

- Gewicht in kg7,24

- d (mm)140

- D (mm)250

- B (mm)42

- C (mm)36

- T (mm)45,75

- Gewicht in kg8,97

- d (mm)150

- D (mm)270

- B (mm)45

- C (mm)38

- T (mm)49

- Gewicht in kg11,6

- d (mm)160

- D (mm)290

- B (mm)48

- C (mm)40

- T (mm)52

- Gewicht in kg14,1

- d (mm)170

- D (mm)310

- B (mm)52

- C (mm)43

- T (mm)57

- Gewicht in kg17,8

- d (mm)180

- D (mm)320

- B (mm)52

- C (mm)43

- T (mm)57

- Gewicht in kg18,3